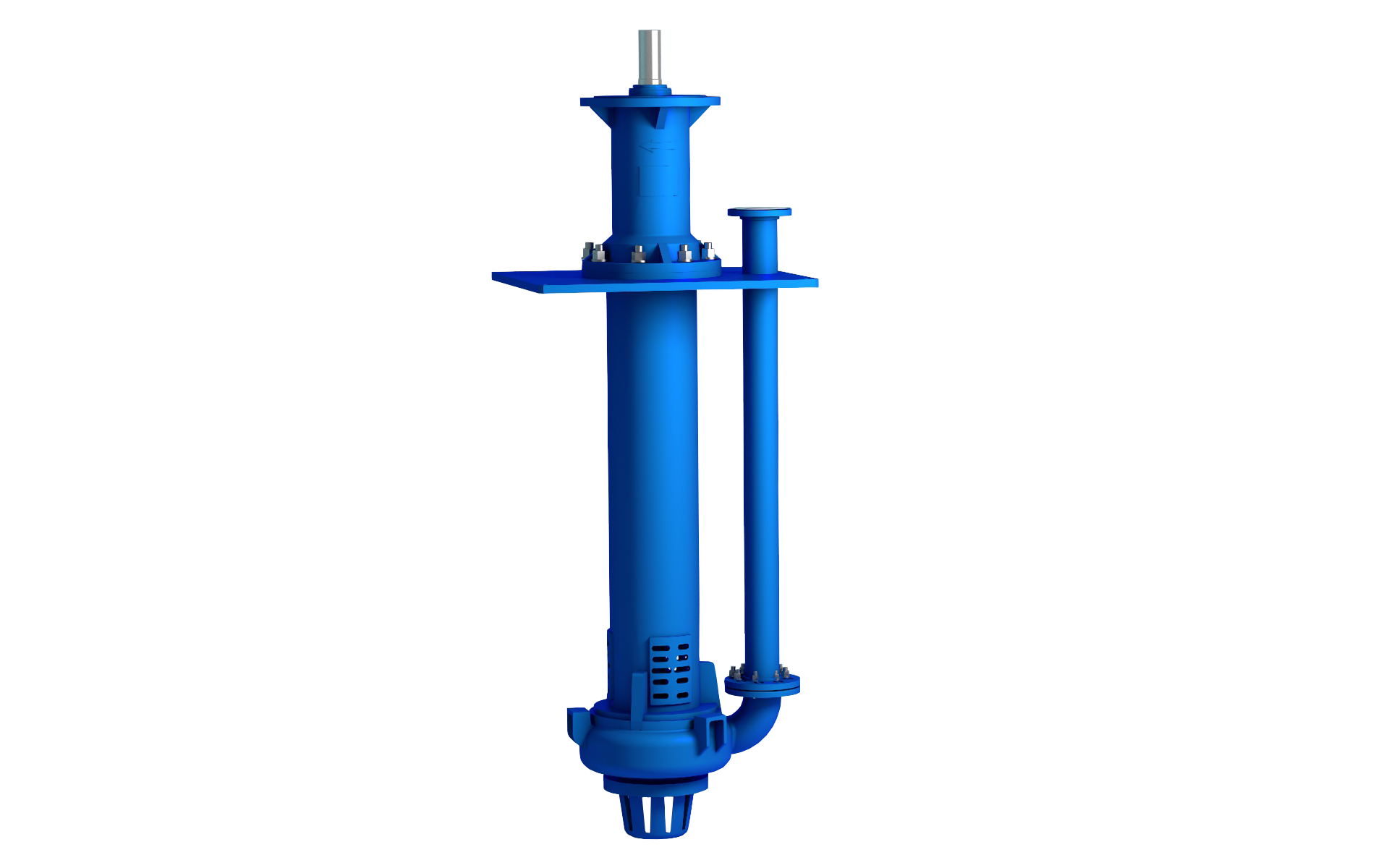

ZGB (P) series high lift slurry pump

Technical parameters:

| Product model |

ZGB (P) series high lift slurry pump |

|

Caliber(mm) |

65~300 |

|

Flow(m3/h) |

60~1800 |

|

Lift(m) |

50~120 |

| Material |

M |

Product features:

Double pump casing structure. It has the characteristics of high lift, high efficiency, good wear resistance, stable performance and good cavitation performance. The lining and impeller materials are made of wear-resistant metal. The pump outlet direction can be installed and used at eight different angles with an interval of 45 °. The pump and driving machine can be driven by direct coupling, hydraulic coupling and reducer. The impeller can also be cut to meet different performance conditions. The shaft seal can adopt packing + auxiliary impeller combination seal or mechanical seal. The bearings are lubricated with thin oil and equipped with two sets of water cooling systems for bearing cooling. The rotation direction of the pump is clockwise from the driving end. It can be connected in series at multiple levels.

Application fields:

It is suitable for medium and high lift applications in metallurgy, mining, coal, electric power and other industries, such as slurry transportation in metallurgy, mining, electric power, steel plant and chemical industry.

SAUNDERS

WRITE A MESSAGE TO US

Kingda pump group Xingtang Pump Co., Ltd

Kingda Pump Industry Group Co., Ltd

Add:Xingtang County, Shijiazhuang, Hebei, China

Tel:0311-85426662/6661

Fax:0311-85426671

Mail:info@kingdapump.com

SEO TAG